Coatings for Fiberglass Roof Decks: You may have come here looking for information about fiberglass roof deck coatings—and we’re here to help. We frequently encounter failed fiberglass roof decks that have been treated by coating contractors offering quick fixes. It’s important to understand that many of these coatings are not actually compatible with fiberglass roof deck membranes. Keep reading as we help clarify this often confusing topic.

MYTH #1 This myth must be busted. Under normal circumstances, FIBERGLASS ROOF DECKS DO NOT REQUIRE COATING EVERY 5 YEARS. Read the following, and you will begin to understand that there are some horrible misconceptions in the industry. Unless you are hosting dance parties every night, your Gel Coat should be smooth and holding up for a decade or two, in many cases. If your deck looks like the images below, call us! While there are many types of coatings available, when applied to a failing fiberglass roof deck membrane, most will not perform as intended because they are simply incompatible with the existing surface conditions. We’ll explain more below. In short, if you’re considering any coating, please get in touch with us first. Don't trust your roof deck to a novice, or middle-man contractor that will only sub-contract the work out to cheaper novices. We can visit, assess, and provide advice and a free estimate for what your roof deck needs from the most experienced contractor in the business.

Many coatings are being promoted in the marketplace today, but if your roof deck surface resembles either of the images above, no coating will provide a lasting solution. When a fiberglass roof deck is failing as shown, the membrane is unstable and constantly shifting—it cannot hold a coating. No amount of sanding or cleaning can restore the chemical integrity of the membrane. We do have solutions for this type of failure, but applying a coating is not one of them.

If your deck shows damage similar to what’s pictured, you cannot successfully coat the surface with any product—including Gel Coat. The failure is the result of installation errors. Attempting to coat a compromised surface will not only fail, it will also create additional damage; by the time repairs are finally made, the plywood will often need to be removed and replaced. Choosing to apply a coating to a roof deck is a serious decision and can become very costly in the short term.

Roof coatings have been around for decades, and year after year, promises of leak repair and restoration have been made—and broken. Coatings are designed to protect a membrane, not become the membrane. When we begin relying on a coating to function as the roofing system itself, problems arise quickly. A coating is not a roofing system, and the damage caused by using it as such can be extensive. This misuse has been proven time and again to result in complete system failure, often requiring full replacement—including the plywood.

If you’re considering coating or recoating your roof deck, please contact us first. We can help you avoid costly mistakes and guide you toward a proper, lasting solution. So while you have been searching for contractor to provide an estimate for coating your fiberglass roof deck, we ask that you give us a chance to explain in detail the very real conditions that may prohibit the effective coating of your deck and save you a lot of heartaches. FREE EVALUATION & ESTIMATE

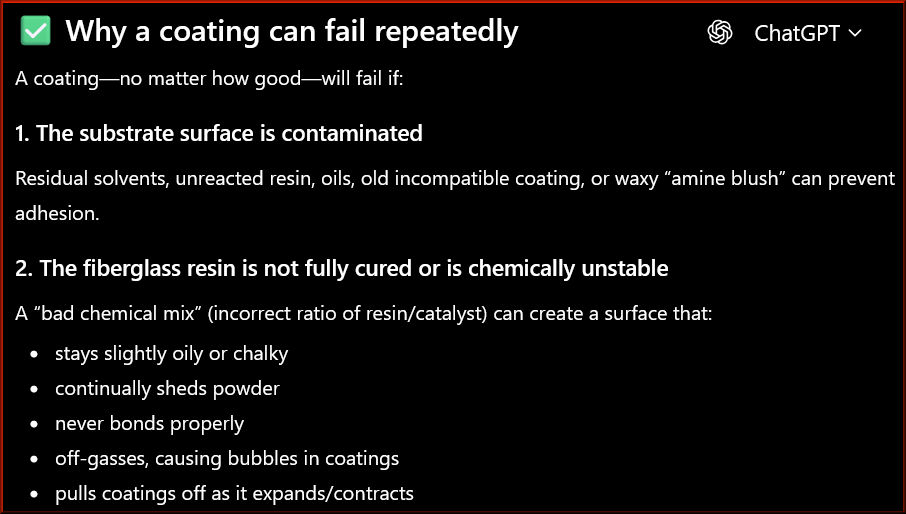

Even an AI search responds with the correct answer. (See below.) How is it that the industry is so far behind from understanding these simple facts? Why are so many roof decks being ruined by misguided coating attempts?

Coatings Other Than Gel Coat

Silicone Roof Coatings

Silicone Coatings are the most prolific of all the coatings. They are expensive and they are of very high quality. The problems start when you try to use them on a fiberglass roof deck. Adhesion is an issue and often additional materials and primers must be used in order get the products to hold on to some surfaces. Silicone failures are near 100% in the city because every time they are tried, they do not adhere well. They hold for a while sometimes but the usual application over the corrupted surfaces fail miserably a few seasons after completion.

Understanding Roof Deck Coatings

There are countless coating options on the market, and in the roofing industry their primary purpose is to protect the membrane. However, the roof deck membrane is a traffic-bearing surface, and most coatings—aside from a few specialized harder products—are relatively soft. Applying a soft coating to a high-traffic area is rarely advisable. More importantly, coating a roof deck membrane that has already failed will always result in failure, regardless of how much surface preparation is performed. Attempting to fix the issue with coatings can lead to significant additional costs, as a full rebuild—or at minimum, replacement of the top layer of plywood—will likely be required. To better understand the correct way to construct a roof deck and avoid these costly mistakes, we encourage you to visit our page on proper roof deck building practices. The Build: It will make or break the deck.

Silicone Not For Fiberglass

A few years ago, several applicators in the city began heavily promoting silicone coatings for fiberglass roof decks, complete with impressive warranties and bold performance claims. Unfortunately, these systems failed in nearly every installation. Even worse (as noted above in the image ‘• migration’) once silicone is applied to a failing fiberglass deck, remnants remain and the plywood must be replaced. Please think carefully before moving forward with this type of coating. It can turn a fixable issue into a far more costly restoration. We’re here to help you make an informed decision.

Polyurea & Polyurethane Coatings

Great Coatings Require the Right Surface. All of these coatings are exceptional—and like all high-performance coatings, their success depends on the condition of the surface beneath them. Just as you wouldn’t paint over rotting wood, a coating should never be applied to a surface that is chemically compromised, unstable, or actively changing. Proper adhesion is critical. Every coating manufacturer emphasizes the importance of thorough surface preparation, including cleaning and abrasion. However, when a membrane has been improperly mixed with incompatible chemicals at the outset, when it was installed, the surface itself prematurely fails or begins to break down in very little time. In these cases, even with correct preparation, the underlying chemical reaction continues. The result: any new coating applied on top will ultimately fail. Ensuring a stable, chemically sound substrate is essential for long-lasting coating performance.

Latex & Urethane & Acrylic Coatings

Many Latex, Urethane, and Acrylic coatings are often listed as being compatible with fiberglass membranes, so our use of the term “non-compatible” needs clarification. The incompatibility is not entirely due to the coatings themselves — it’s due to the condition of the fiberglass at the time of application. When a homeowner decides to coat a roof deck, it’s usually because the surface is already failing. A chemically deteriorated or compromised fiberglass surface is not suitable for any successful coating application. If your roof deck looks like either of the pictures above, showing chipping, cracking, or alligatoring, do not coat it. Applying coatings over a damaged fiberglass surface can lead to serious and expensive problems, including plywood replacement, because once these products are applied, they cannot be removed entirely. In most cases, membrane repair is no longer possible, and a complete rebuild becomes the only option. Keep in mind that while there are many coating and reinforced coating systems available, none of them can guarantee success when applied to a questionable or compromised substrate. Another fact is that most “paint warranties” cover product replacement only—not labor, failure, or resulting damage.

Coatings Can’t Fix a Failed Roof Deck

Applying a coating to a roof deck membrane that has already failed will always fail—no amount of surface preparation can prevent it. Many coatings advertise “flexibility,” but this prized property of their product is designed to absorb some movement from a substrate, allowing the coating to expand and contract with movement. (Maybe you would like to read more about these ‘movement’ and ‘flexibility’ issues on our ‘Myths & Facts’ page for better understanding.) When a flexible coating is applied over an unstable fiberglass roof deck, it can lead to separation, bubbling, and further damage. Attempting to fix a failed deck this way can be costly, often requiring a full rebuild—or at minimum, replacement of the top layer of plywood.

Gel Coat will not even work when the deck surface is failing

So many roof decks in the city of Philadelphia, done by amateurs where failure has occurred because of bad chemical mixes, bad prep or bad deck builds, are routinely re-coated only to have the coating fail miserably. Even Gel Coat will fail if applied to a corrupted surface. So not you know more than a lot of contractors who will visit and suggest a coating when the roof deck membrane will not hold it. Call us and we can help. We can provide free expert advice and an estimate for the proper and lasting job.

Roof Decks are complicated

We have the knowledge

Re-Coating May Seem Harmless—But It Isn’t! Re-coating a roof deck can seem like a simple, harmless solution—but in many cases, it actually makes the problem worse. Before you invest in another temporary fix, reach out to us. We’ll give you the complete, honest picture that many contractors overlook, so you can make an informed decision and protect your investment.

1000's of roof decks

Skilled Technicians Trained by Industry Veterans Our technicians understand every detail of your rooftop. Trained directly by industry veterans, they bring expertise, precision, and true craftsmanship to every project. We are proud of the artisans who transform each roof deck into a beautiful, durable space—and a lasting reflection of our commitment to quality and success.

No Subcontractors

In today’s construction world, many builders and middle-man contractors rely on single-trade applicators—chosen mainly because they’re inexpensive and fast. Unfortunately, this approach often leads to inconsistent workmanship and poor long-term results. At our company, we do things differently. We use only our own employees, all trained directly by our veteran staff. This ensures that every project receives the same level of care, craftsmanship, and attention to detail as the many successful installations we’ve completed throughout the city. Rest assured—your home is in expert hands.

We show up first in the search engines, not because we pay for position, but because we have been here the longest and we offer the most and best content. No fake reviews. No spammy social media.

We show up first in the search engines, not because we pay for position, but because we have been here the longest and we offer the most and best content. No fake reviews. No spammy social media.